Alumina Ceramic

What Is Alumina Ceramic?

Alumina ceramic, also known as alumina or aluminum oxide (Al2O3), are a versatile and high-performance type of industrial ceramic. Renowned for their exceptional hardness and thermal conductivity, alumina ceramics are widely used in applications demanding structural integrity, wear resistance, and corrosion resistance.

Contact us today to discuss your alumina ceramic requirements and request a quote.

Properties of Alumina Ceramics

Alumina ceramic, or aluminum oxide (Al2O3), are valued for their superior performance in various industrial applications. Key properties include:

- Alumina Content: Available in purity levels from 99% to 99.8%, higher alumina content offers enhanced resistance to wear, corrosion, and electrical conductivity.

- Crystal Phases: Variations like mullite and corundum impact mechanical properties, making them suitable for different uses.

- Additives: Additives such as chromium and titanium enhance specific properties, allowing for tailored solutions.

- Electrical Insulation: Alumina is an excellent electrical insulator, with resistance increasing with purity, ideal for high dielectric strength applications.

- Thermal Properties: It has a high melting point and strong mechanical strength, though this strength decreases above 1000°C. It also has excellent thermal conductivity but lower thermal shock resistance.

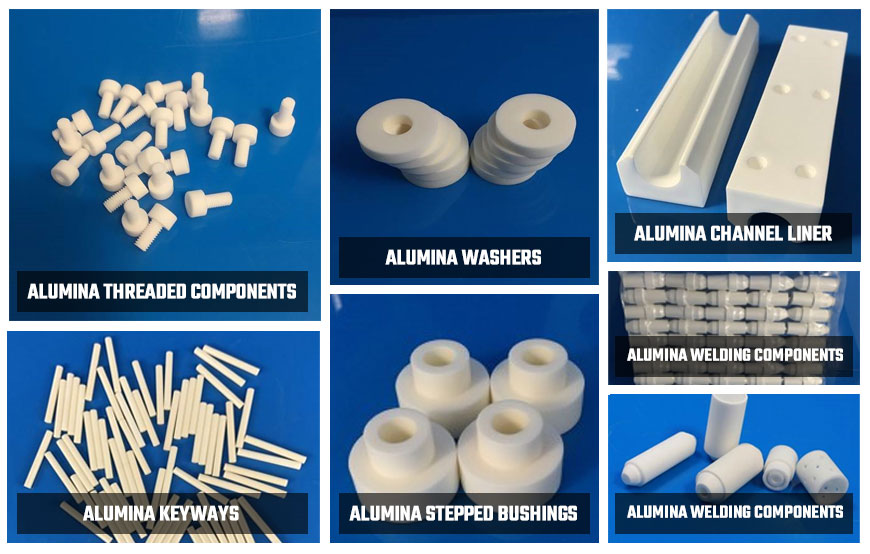

Applications of Alumina Ceramics

The unique properties of alumina ceramics make them suitable for a wide range of applications:

- Acid-Resistant Components: Used in acid-resistant pump parts and pipe linings due to their chemical stability.

- Textile and Metalworking: Their hardness and wear resistance are ideal for textile wear parts, knives, and abrasive grains.

- Abrasives: Commonly used as abrasive grains in woodworking and metalworking for better performance on various materials.

- Lighting and Detection: Transparent alumina is used in high-pressure sodium lamps and infrared detection windows.

- Electrical Insulators: High-purity alumina serves as an excellent electrical insulator with low dielectric loss, making it ideal for electronics.

Contact Technical Ceramics today to discuss your requirements or request a quote.

All products are fired in one of our temperature controlled continuous tunnel kilns, capable of very high production runs up to a few hundred thousand parts per month.

Download brochure

make an enquiry today

At TCA, our customers are at the core of what we do. So why not contact us today to discuss your needs? If we don’t have an existing solution, we can look at creating one especially for you!